Our effort in environmental sustainability includes investments in air pollution control equipment, recycling many types of non-product outputs including wooden pallets, cardboard, electronics, white paper, as well as many other things. Additionally, we have an established Energy Reduction Task Force that is charged with minimizing total plant energy usage through investment of new technology and continuous improvement activities.

Safety

At Logan Aluminum our vision is to demonstrate an increasing capability to operate injury free and to eliminate all “Life Changing Injuries”.

Safety Principles

- Safety is Non-Negotiable

- Logan Aluminum has an expectation that all work can be performed injury-free. All team members will hold themselves and each other accountable for behaviors in accordance with safe work practices.

- All levels of the organization will clearly communicate in word and deed that safe work behaviors are expected.

- An injury-free work environment requires a cultural change and ensures team members have information, authority and resources required.

- Significant cultural and behavioral change is required, and it will happen with participation and involvement of all team members and is worth the effort required.

- Application of scientific methods, behavioral science, and statistical tools are critical to achieving injury free capabilities.

- At-risk behavior is the best predictor of safety performance.

Environmental

“We shall strive to reduce our environmental footprint and risk profile for Logan Aluminum through superior operational performance and compliance to achieve environmental excellence in all areas.”

We shall:

- Meet or surpass all governmental requirements

- Reduce the severity of environmental incidents

- Reduce, reuse and recycle process materials and waste streams

- Review and advocate effective pollution control technologies and best practices

- Continue to improve environmental communications, quality of environmental reporting and follow-up, training and awareness programs.

Sustainability

Logan Wetlands

The Logan Aluminum Wetlands is a man-made ecosystem spanning over 40 acres, which acts as a natural filtration of our processed wastewater and reduces our dependence on energy and treatment chemicals. Our Wetlands have been naturally filtering our processed wastewater since 1992!

Aluminizing Ground / Air Transportation Industry

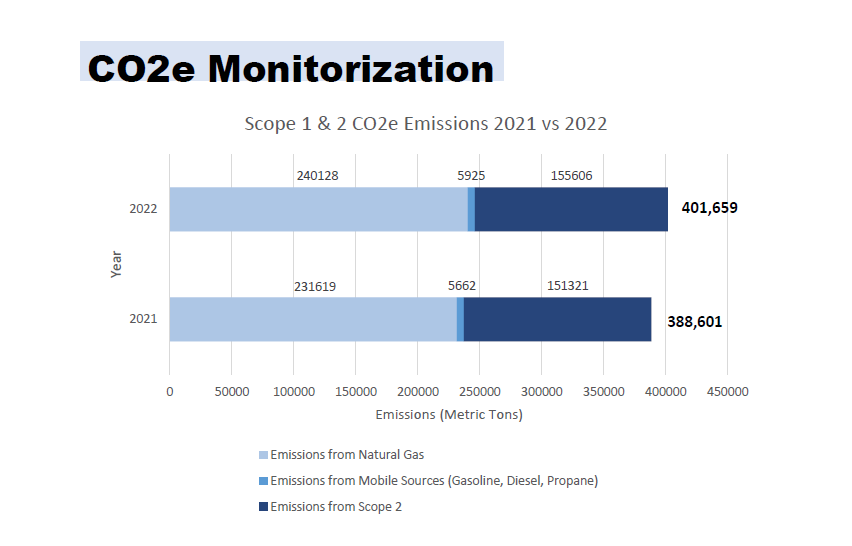

Reduction of GHG emissions

Track and monitoring Environmental Performance

Cardboard, eWaste Recycling Programs

Landfill Waste Reduction

Styrofoam Reduction

Wetlands and Forested Areas

Waste Minimization Program

Biodiversity | Ecological Value of Site | Planning

Water Use Reduction | Efficiency Program

Sustainability Metrics

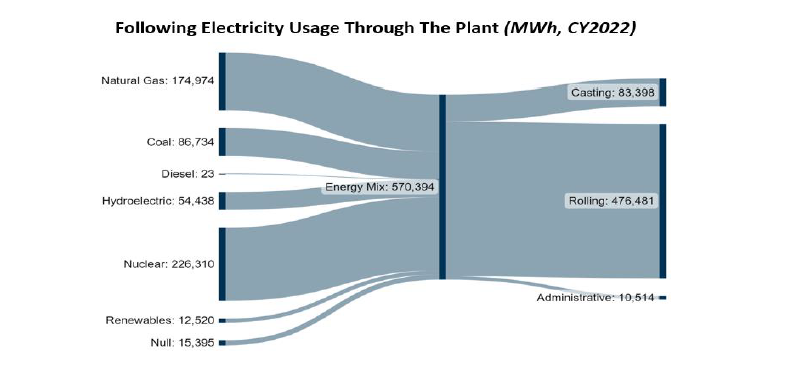

Reducing Energy Intensity

Green House Gas Emissions